FEATURED SOLUTIONS

Three GRP Products. Unlimited Applications.

GRP Structural Profiles

GRP Structural Profiles

GRP Handrails

GRP Handrails

GRP Ladders

GRP Ladders

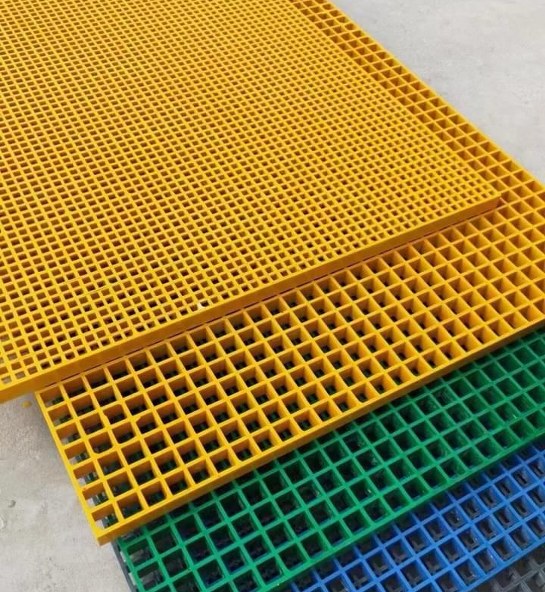

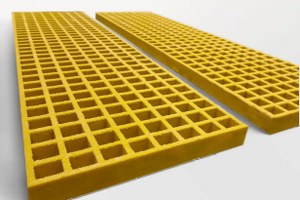

GRP Grating

GRP Grating

| Product | What It Replaces | Benefits |

|---|---|---|

| GRP Profiles | Steel Angles/Channels | High strength-to-weight ratio, no corrosion, fast modular assembly |

| GRP Handrails | Steel Angles/Channels | High strength-to-weight ratio, no corrosion, fast modular assembly |

| GRP Ladders | Steel/Aluminum Ladders | Safer in wet environments, lightweight, rust-free |

| GRP Gratings | Steel/Aluminum Gratings | Anti-slip, chemical resistant, ideal for platforms, walkways, & drains |

WHY INDUSTRY LEADERS CHOOSE US

GRP structures built to perform nonstop in the toughest industrial conditions.

GRP ladders, handrails, and platforms ensure safety with fire-resistant resin and anti-slip surfaces.

GRP products are 70% lighter than metal with steel-like strength for easy handling and installation.

GRP component resists rust, rot, and chemicals, making it perfect for outdoor and corrosive areas.

GRP needs no repainting or repairs, offering zero maintenance and long-term savings.

Replace old steel with modular GRP upgrades that fit existing spaces without structural changes or heavy tools.

GRP delivers long term ROI with durability, safety, and low maintenance, making it ideal for both legacy and new projects.

APPLICATIONS ACROSS SECTORS

Marine & Offshore Platforms

Oil & Gas Refineries

Wastewater Treatment Plants

Industrial Warehouses & Factories

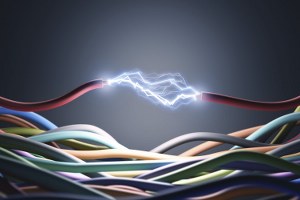

Power Plants & Substations

Chemical Storage Facilities

Public Transport Infrastructure

From Concept to Commissioning

– THAT'S OUR PROMISE

-

Consultation & Design Support

Share your drawings or requirements — we help optimize for durability and budget.

-

Precision Manufacturing

Made with high-grade E-glass roving and IFR-25 fire-retardant resin systems

-

On-Time Delivery & Site Integration

Prefabricated components delivered ready for install — with on-site support if required.

WHY PROFESSIONALS PREFER GRP

Corrosion Resistance

Unlike metal, GRP doesn't rust or weaken in moisture-rich and chemical-prone environments.

Lower Installation Cost

Lightweight components reduce transport and labor costs dramatically.

High Strength-to-Weight Ratio

GRP delivers the structural strength of metal with a fraction of the weight.

Zero Electrical Conductivity

Safe for electrical zones, substations, and high-voltage areas.

Minimal Maintenance

No repainting, no rust-treating, no frequent replacement.

RISK AVOIDANCE!

Don't Let Outdated Metal Cost You More